A heat exchanger facilitates the transfer of heat from a gas or fluid to another fluid or gas without the two mixing or coming into direct contact. It is used to cool or heat one medium using another one close by. It applies the principle of the flow of heat from a hot to cool medium. There are various types of heat exchangers, and they have many applications, including power stations, space heating, refrigeration and cooling, and chemical plants.

The heat exchanger consists of metal shells and tubes with a high thermal conductivity that allows heat transfer. The metal shells prevent the two fluids from mixing, allowing heat to transfer efficiently. The heat transfer process is not affected by the shape of the exchanger since it uses the relative flow of liquid in the tubes.

There are different ways in which the actual heat transfer happens depending on the flow of the medium. In a parallel flow method, the two fluids flow in opposite but parallel directions in separate tubes. This method is very efficient and allows heat transfer in a short time. In a concurrent flow method, one fluid flows from left to right while the other floes from top to bottom. The other way is the cross-flow type, where the two liquids cross at a 90-degree angle.

Types of Heat Exchange

There are various types of heat exchangers varying in different shapes and sizes. Generally, there are three heat exchangers types: shell and tube, regenerative, and plate type heat exchanger.

Shell and Tube Heat Exchanger

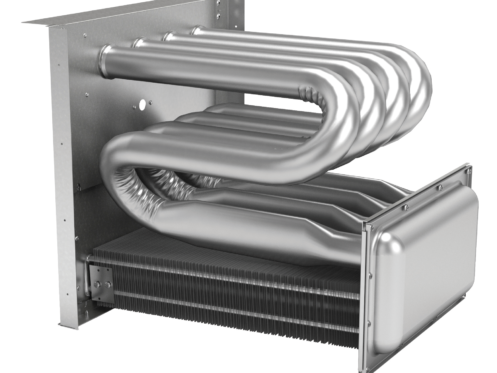

This type of heat exchanger is the most commonly used due to its compatibility with all types of fluids and gas. It consists of a large cylindrical shell casing and several small tubes inside. The tubes can run parallel to each other or bend to form a u-shape.

Shell and tube exchangers with tubes welded to the shell are very economical due to their simple design. They also allow easy manual cleaning of the tubes using typical chemical cleaning procedures. The two fluids are in the shell and the tubes while the heat transfers from one medium to the other. The shell has inlets and outlet nozzles, while the tubes have a front header to let the fluid in and a rear heater to let the fluids out.

The tubes used in shell and tube heat exchangers are thermally conductive to allow the transfer of heat. They are also under constant thermal stress due to temperature changes. The tubes must also be durable and corrosion-resistant. They must be compatible with the fluid and not react with them.

The heat moves from a hot medium to a cooler one in a shell and tube heat exchanger. The cooling medium flows through the tubes while the other medium flows around the tubes in the shell. The shell structure has baffles that increase efficiency by creating turbulence and preventing the formation of hot and cold pockets.

A bypass valve controls the temperature of the output medium by decreasing or increasing the flow of the cooling fluid. The cooling medium flows at a lower pressure than the cooling medium to prevent them from intermixing after a leakage.

A Regenerative Heat Exchanger

A regenerative heat exchanger transfers heat indirectly from one medium to another through a heat storage medium. It is used when one medium has a lot of dissolved impurities or forms a heterogeneous mixture. A regenerative heat exchanger requires less maintenance, is easy to use, and can handle large fluid volumes. However, its design makes it difficult to calculate its efficiency and actual heat transfer.

Plate Heat Exchanger

A plate heat exchanger consists of thin plates made of stainless steel or titanium that help to transfer heat from one medium to another. They have a large surface area which increases their efficiency and makes them easy to clean.

Heat Exchangers in HVAC

Heat exchangers are present in HVAC units such as air conditioners and furnaces. In gas furnaces, heat exchangers increase the temperature of the air, which is then circulated throughout the home during the cold months. It facilitates the exchange of heat from the combustion process to the air flowing through it. It also prevents toxic combustion gases from mixing with the heated air.

The gas furnace has burners that produce combustion gases that enter the heat exchanger through the first opening. The blower also blows indoor air over the heat exchanger. The hot combustion gases heat the indoor air and then exit the heat exchanger to be circulated in your home. The exhaust gases from the combustion process exit the heat exchanger through the flue to the outdoors.

Common Heat Exchanger Problems

Heat exchangers play a vital role in heating your home and improving your health and comfort. However, they are also affected by various problems that can affect their efficiency. Here are some of the common issues facing heat exchangers.

Rust and Corrosion

When there is excess condensation in the furnace, the heat exchangers can rust. Furnaces have a drainage system that removes condensate to prevent corrosion. A blocked drain line can prevent the flow of condensate out of the furnace. After some time, the condensate corrodes the heat exchanger and allows exhaust fumes to escape.

Cracks and Holes

Cracks and holes in the heat exchanger can prevent your furnace from producing enough heat. It can also cause toxic combustion gases such as carbon monoxide to enter your home. These gases are dangerous to your health and can be fatal when inhaled for an extended period. The most common cause of cracks in a heat exchanger is overheating.

Your heat exchanger can overheat due the following reasons:

- Dirty air filters

- Combustion problems

- An incorrectly sized furnace

- Worn out pressure valves

- Lack of regular furnace maintenance

Heat exchangers are subject to wear and tear, and after some time, they experience mental fatigue due to the expansion and contraction. This can cause cracks and holes in the material. Corrosion and growth of biological contaminants in the heat exchanger can cause it to produce an unpleasant smell.

You can detect problems with your heat exchanger if you notice the flame color is not blue. If you see a bright yellow flame, it could signify a leak allowing oxygen to enter the system. Soot buildup inside the heat exchanger is also a sign that your heat exchanger is damaged. The soot can decolorize the metal in the heat exchanger.

Heat exchangers require frequent maintenance to keep your furnace running efficiently. It also prevents frequent breakdowns and prolongs the service lifespan of your system. Heat exchangers need to be cleaned to remove deposits and reduce susceptibility to corrosion.

Scheduling a professional tune-up for inspection can help prevent common heat exchanger problems. The HVAC technicians will check for any leaks or cracks and repair them. If your heat exchanger is past its service lifespan or it’s too damaged for repair, you may have to replace it. Ensure that you have qualified and experienced HVAC technicians to install your heat exchanger. It should also be correctly sized for your furnace to ensure maximum efficiency.

Sano Heating & Air Conditioning provides professional heating and air conditioning services in Orange County. We offer exceptional customer service and products that you can always depend on. Our team is equipped with the skills and experience to find solutions that are the right fit for your home. Contact Sano Heating & Air Conditioning today for more information!